Make T-shirt printing quick and creative

with Roland DG digital printers

On-demand digital printing is an exciting option for established T-shirt and apparel businesses. A truly complementary technology to screen printing, digital printing can accelerate the production of unique T-shirt designs while maintaining quality control and creativity. Alternatively, the affordability and ease of use of digital T-shirt printers provides an accessible entry point to entrepreneurs beginning to explore this market.

Opportunities for T-shirt printers

Research carried out for the FESPA Print Census report has found that fast fashion, textiles for garments and sports apparel are growing applications for textile businesses – and that 56% of relevant businesses have made digital investments.

The same census revealed the reasons that textile print businesses gave for investing in digital devices: reduced turnaround times, the ability to produce prototypes, the potential for customised creative work and a smaller environmental footprint from a reduction in water and energy consumption. T-shirt businesses can gain from all these benefits and more.

Room for creativity and profit

T-shirt printing is one of the smartest, coolest and most fun markets you can approach. Guess why? It opens up space for creativity and design. In theory, every T-shirt – personalised T-shirts, graphic T-shirts, vintage T-shirt designs and long-sleeve custom T-shirts – can become iconic yet always be on trend, appreciated by people of all ages. T-shirts are always in fashion, they are used as promotional tools everywhere: TV series, sports teams, bands, brands and many more.

Creative, durable T-shirt designs

Let's deep dive a bit into technology and see how digital T-shirt printing can help make your business profitable, individual and ready to stand out from the crowd.

Digital printing technology has evolved to offer the full gamut of colours, regardless of the colour of your base material. An essential thing to know is that there is a choice of different digital printing technologies suited to T-shirt customisation, with different entry and consumables costs. Rest assured there is an option to suit any budget.

Heat transfer is one common method of T-shirt customisation with two technology options. Firstly, heat transfer material can be cut, using a cutting plotter, and transferred onto the fabric. There are dozens of materials available to cut and transfer onto T-shirts – vinyl, flock, stretchable, 3D – to make your designs come to life.

Secondly, you can print your design onto heat transfer material and cut it to the perfect shape using a using a combination print and cut device, such as a Roland TrueVIS printer/cutter. With Roland print-and-cut, you can achieve deep blacks and bright colours, reliable CMYK and super-accurate brand colours on your tees

You can also print directly onto the T-shirt using a process called direct-to-garment. In this case, T-shirts are pre-treated, printed and then dried in a special textile oven. Alternatively, the Roland BT-12 direct-to-garment printer removes the pre-treating stage to accelerate production.

Some businesses combine an analogue T-shirt printing process, such as screen printing, with digitally printed aspects to produce fantastic designs – both one-offs and longer runs.

Last but not least, you can use sublimation printing to create designs on polyester T-shirts. Here the process is a bit more complicated. The dye-sublimation printer must be flanked with a calender or heat press to transfer the colour from the paper (onto which you print) into the fibre.

The result is astonishing because the ink bleeds into the fibres of the cloth rather than sitting on top, leaving a soft texture or no texture at all – just the feeling of your chosen material. Sublimation technology is mainly used for sports shirts and hoodies. Prints are durable and washable, so this allows designers to really get creative and deliver exactly what their customers want, down to the last unique detail.

One-of-a-kind T-shirt designs

or runs of hundreds

Whichever digital printing technology you choose – heat transfer with a plotter, print-and-cut, direct-to-garment or sublimation – each is designed to make it as simple to print one T-shirt as it is to print hundreds, thanks to the variable data software supplied with your system.

Indeed, the software is one of the strengths of digital T-shirt printing systems. The print management software allows you to switch colours, text, logos, size and any other aspect for every T-shirt design, or group graphic types together through the software's nesting function to optimise material used and cut down on waste. The process is so quick and straightforward that you can even invite your customers to be involved in the printing experience.

It's just as easy to print dozens of identical T-shirts and sweatshirts. You can quickly experiment with colour, text size and image quality to ensure your design is 100% accurate, avoiding costly misprints without having to begin the process again.

T-Shirts

Tote bags

Baby clothes

Sweatshirts

Décor

A T-shirt printer to fit your workspace

There are a variety of printing technologies that are compatible with T-shirt printing, and a range of hardware sizes to make it possible for businesses of any type to add a printer to their workspace. The smallest are genuinely desktop-sized to fit into the smallest studios, pop-up shops or kitchen tables, while the largest are serious business-builders for T-shirt brands.

Each Roland printer includes RIP (Raster Image Processing) software. The software also ensures optimal control, quality and accuracy across multiple printers of the same type for maximum production in larger workrooms with space for several machines.

Low set-up costs, highly versatile

To get started in digital printing, you'll need the hardware with bundled software, the material or product on which you'll want to print, and inks. This makes set-up easy and affordable and the process simple enough to fit into an existing workflow and daily routine.

Here at Roland DG, we have designed our devices with the operator in mind, including those with no previous printing experience, to help any new user to start printing incredible T-shirt designs after a short training session. This is also where the support and online guidance from Roland and its global community boosts the technology's potential for creating profits and creativity.

Technology options for your T-shirt business

Whether you're complementing your screen printing process or starting a fresh new T-shirt printing business, Roland can meet your needs with a number of different digital printing technologies. All are safe, clean and easy to use to achieve amazingly accurate reproductions of your designs – and many have different size options to choose from.

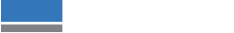

Heat transfer cutting

Cutting devices are the simplest starting point to build your T-shirt business. Cutters such as the Roland GS-24 or GR Series can cut several types of materials. These materials can also be combined and then transferred onto the T-shirt (or hoodie, cap, cushion, and so on) through a heat press. You can use 3D materials made from polyester that expand when heated, or thick, reflective, metallic, holographic, glittery, varnished, electric-bright, photoluminescent or stretchable materials.

The process is straightforward. You draft your design in the software and then send the file for cutting. Once the excess material is peeled away, the graphic is ready to be applied through the heat press.

Heat transfer printing

Add your designs to T-shirts quickly and easily with heat transfer printing. Also called digital transfer or thermal transfer printing, this process involves printing the image or text onto a sheet of garment vinyl, then applying heat and pressure. This 'melts' the vinyl bonding to the garment. You can print in bright CMYK, and onto a variety of transfer materials like those with eye-catching metallic and pearlescent finishes. You can even add effects like flock, 3D and embossing to your T-shirts, hoodies, caps and children's clothes.

The Roland VersaSTUDIO BN-20 is a desktop printer/cutter perfect for businesses starting out in T-shirt printing, while offering the added flexibility to produce stickers, window decals and labels too. Roland's larger digital printer/cutters – such as the TrueVIS range – are a great option for T-shirt businesses looking to diversify, as you can produce banners, vehicle graphics, posters and more on the same device.

Dye-sublimation printing

Dye-sublimation printing uses heat and pressure, with a machine called a calender or heat press, to apply designs to polyester materials. Because the dye, or ink, sits inside the structure of the fabric this printing process creates extra-durable and washable designs – perfect for sportswear and workwear. Dye-sublimation is also compatible with hard surfaces like cycle helmets and coffee mugs, as well as other fabric-based products like flags, meaning businesses can offer a wide range of products to their customers. The Roland Texart dye-sublimation printer range delivers amazing colours, from pastels to fluorescents to deep black tones.

Direct-to-garment printing

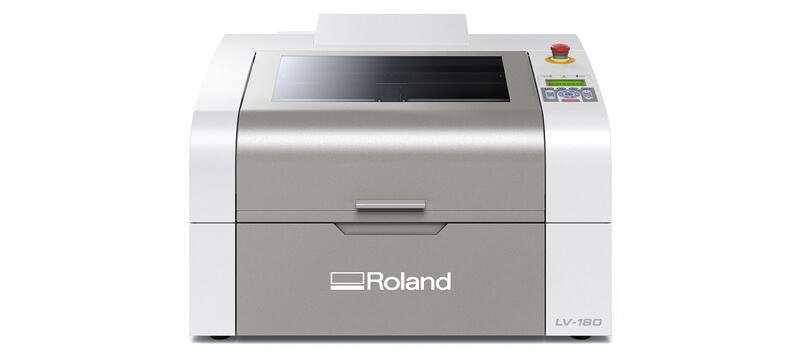

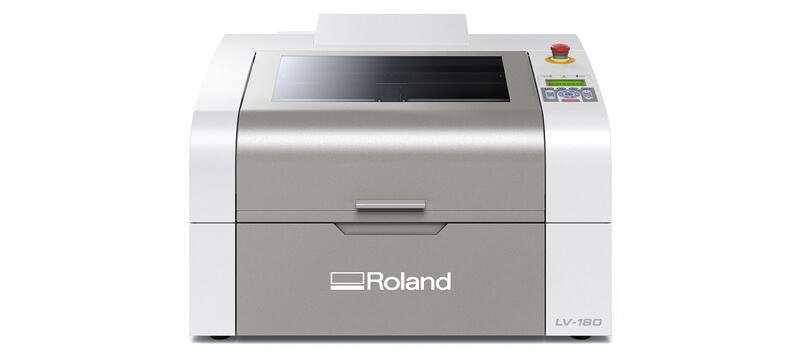

Laser engraving

For fashion brands looking to offer something different alongside their T-shirt designs, Roland LV series laser engravers offer amazing material versatility. Using a non-contact CO2 laser you can cut and mark the most intricate shapes on leather, vegan-friendly alternatives like cork, and thick fabrics such as denim, quickly and safely. LV is also great for cutting and engraving designs on acrylic and wood for must-have jewellery and accessories.

Start your T-shirt business

Roland offers all the equipment you need to create beautiful and unique T-shirts. Whether you want to extend your current printing business or create a new one, we suggest first deciding on your own visual identity, brand and logo. Then, develop a business plan and decide who is your target market. Doing this will help you decide the look and feel of your graphics.

We recommend you consider an e-commerce platform or offer a kiosk service (such as Roland cotodesign) to build your business and – if you don’t already have one – a website. You should also select the suppliers for your blank T-shirts and printing materials. If you need help, our Roland dealers can help you find the right ones.

Software

Maximise the potential of your T-shirt printing systems with intuitive software from Roland. Our packages can help you expand your range of products, simplify processes and engage your customers.

PersBiz

Roland's cloud-based PersBiz solution is ideal for online T-shirt businesses and those with two or more locations. Your customers can select and personalise a product from a catalogue defined by you, and order online. Product range management, order handling, payment and delivery options are all simplified by the program, so you can focus on personalisation.

PersBiz is a scalable, modular solution that is available in two packages: PersBiz eCommerce and PersBiz Business eCommerce.